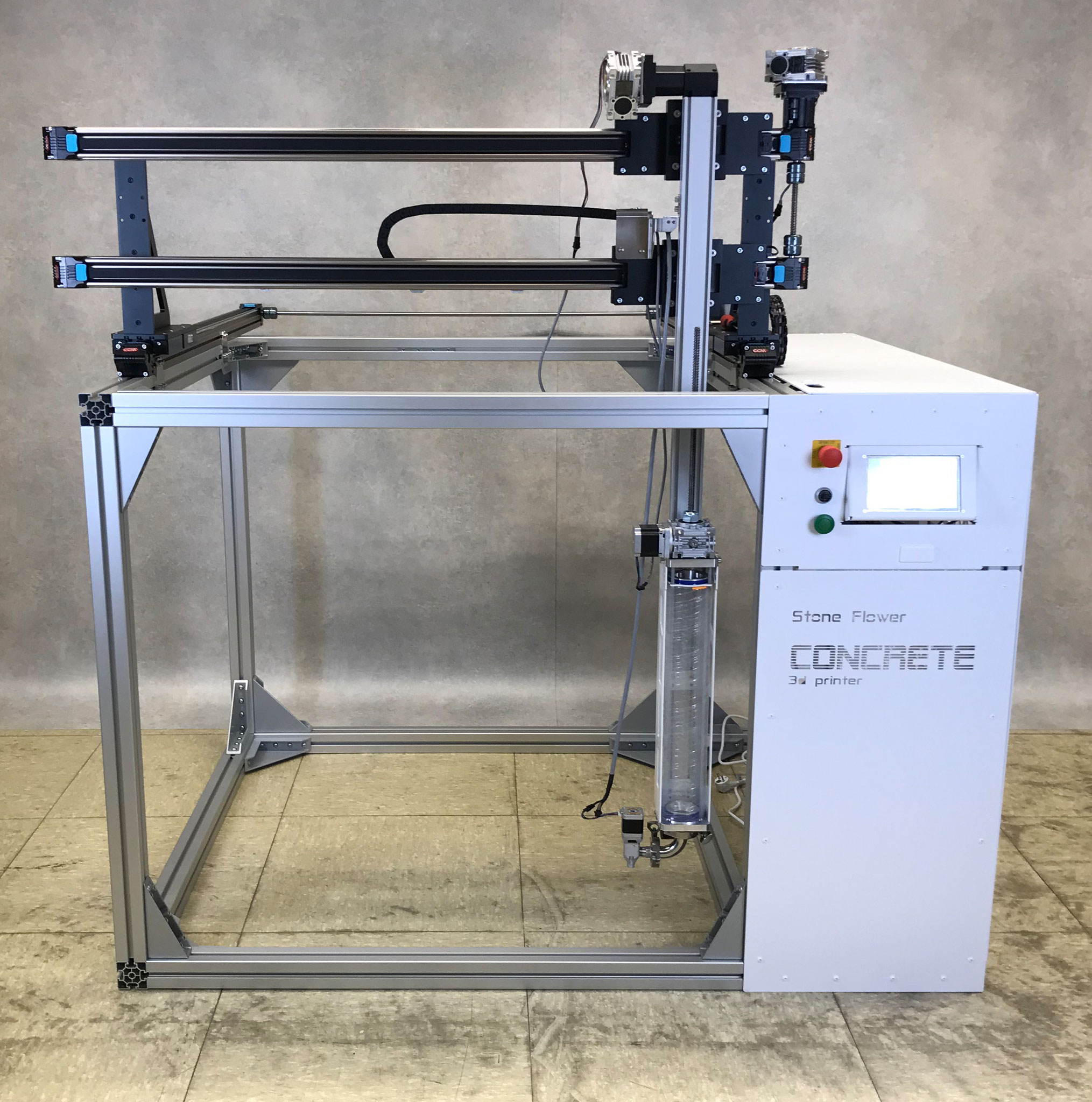

Concrete 3D printer

Easy-to-use laboratory 3d printer for mortars, cements with the aggregate size up to 6mm, suspensions, and clays. You can customize maximum printing dimensions according to your needs and budget. 3D printer is operated via touch-screen, or remotelly, through the web interface. Designed to be precise, fast and user-friendly. Installation and teaching are inlcuded in every purchase.

Applications

Small-scale 3d printing of mortar, cements, suspensions and clays. Can print both single and two-component rapidly hardening materials throung our mixing 2K print head for cement.

Custom build volume

Width: from 50cm to 150cm

Depth: from 50cm to 300cm

Height: from 50cm to 120cm

High speed and precision are attained due to rigid frame reinforced with corners, and massive steel plates. Standard rectangular geometry of the build volume makes the printer easy-to-use.

Specification

- Includes router and 2K mixing print head for motar (see below)

- Flexible input voltage 110-230V AC, 600W (tanks to high-quality switching power source)

- Industrial belt drives from CCM, linear guides from hardened chromed stainless steel

- Electronics Duet 6HC

- Interfaces: colorfull 7 inch touch screen, SD card (32GB), USB port, Ethernet port, web interface

- Motion speed

Width, Depth: up to 200mm/s; Height: up to 15mm/s - Compatible pumps: progressive cavity mortar pump, ram extruder (syringe pump, up to 5L), compressed air feed system

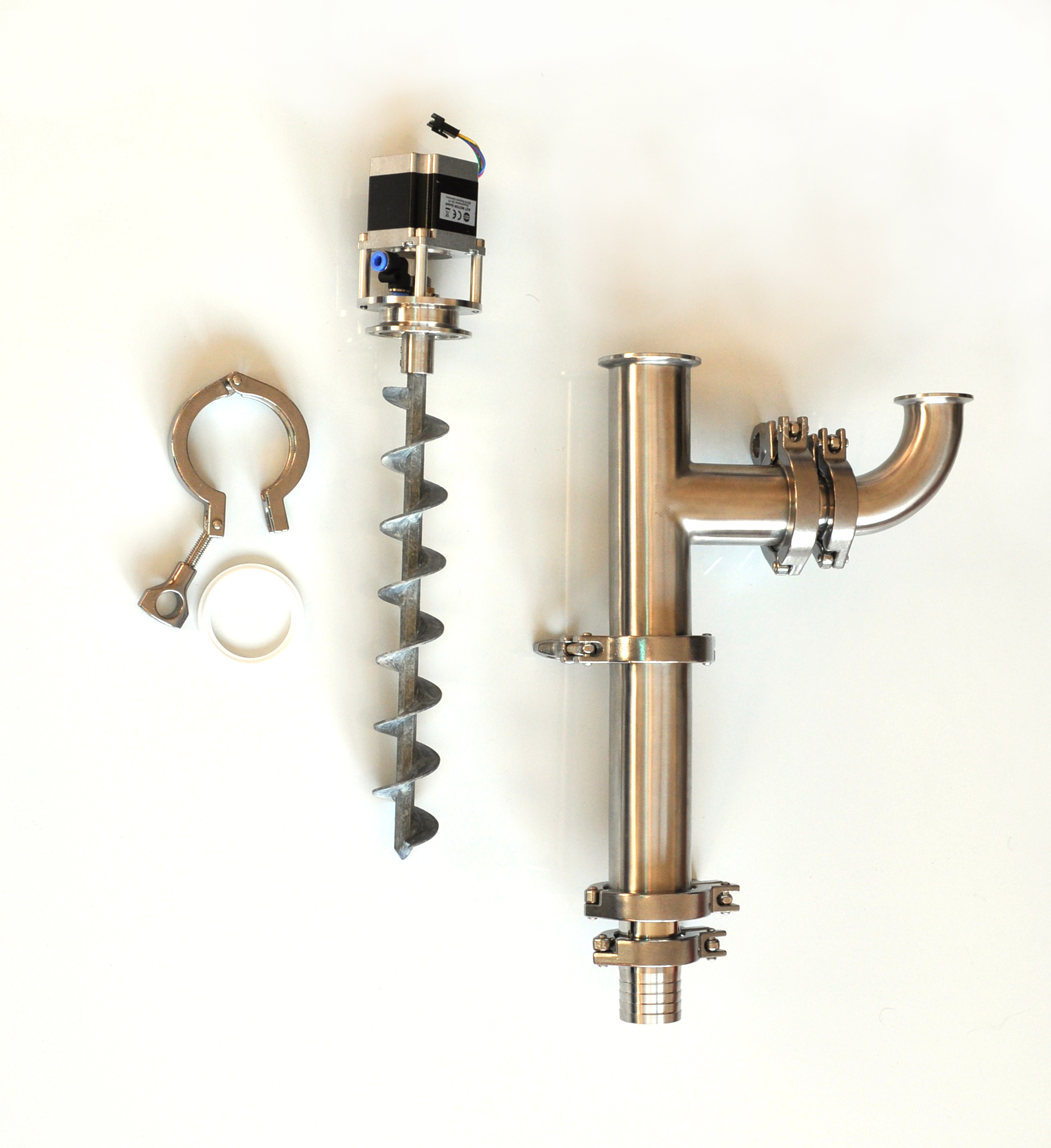

Mixing print head

Print head, supporting one or two rapidly curing components, homogenize them at the speed up to 300rpm. Material flow up to 5l/min. Equipped with back flow valve to prevent curing in pipes. The rotor has replaceable blades for long operation. Standard tri-clamp fitting help to combine the print head with different pump (5L ram extruder or continuous mortar pump), and different nozzles. Compatible standard nozzle sizes vary from 3 to 35mm.

- Stainless steel 304

- Diameter 50mm

- Main inlet ID = 25mm, tri-clamp connector

- Second inlet (for accelerator, optional), 12mm

- length 450mm

- comes with nozzle 35mm (you can request other nozzle shapes and sizes as well).

Price estimate

Please choose required dimensions of the printing volume below:

WIDTH: cm

DEPTH: cm

HEIGHT: cm

Estimated Netto price: EUR

Disclaimer: The estimation above provides the minimal netto price of the router + print head. Taxes, potential custom fees, shipping costs and installation costs, are not included, since they depend on your location. Costs of additional customization, mortar pump, spare parts, are not included.

Compatible pumps

Progressive cavity pumps, 50L

- Variable speed

- Power 220V AC, 1700W

- Maximum flow rate 10L/min

- Maximum pressure 20bar

- Maximum pumping distance 15m

- Maximum pumping heght 10m

- Maximum grain size 6mm

- Capacity 50L

Contact us for quote!

* Please specify printing volume of your printer (WxDxH, cm), type of mortar pump (if required), and add your shipping address to let us evaluate the shipping/installation costs for you.

2 VAT isn't charged on exports to countries outside the EU. In this case the VAT is paid in the country of import. Upon purchase from non EU country, please select the option "Invoice" to get the price without VAT.

3 including tax